Cargo nets are indispensable tools for securing loads during transportation. Whether you’re hauling equipment, personal belongings, or commercial goods, a reliable cargo net ensures that everything stays in place safely. While there are many pre-made options available on the market, making your own cargo net can be both cost-effective and customizable. The key to crafting a durable and strong cargo net lies in the careful selection and use of cargo net webbing, a heavy-duty material designed to withstand extreme pressures.

This guide from Nets Depot Inc will take you step-by-step through the process of making a cargo net, discuss the necessary materials, and answer some frequently asked questions. By the end, you’ll not only know how to make a cargo net but also understand the intricacies of its design and structure to best suit your needs.

Materials Needed

Before you begin, gather all the required materials. Building a durable cargo net largely depends on the quality of the materials you use, especially the type of cargo net webbing.

Here’s what you’ll need:

- Cargo net webbing (polyester or nylon)

- Heavy-duty scissors or cutting tools

- Industrial-grade thread (UV-resistant for outdoor use)

- A heavy-duty sewing machine

- Carabiners or metal hooks

- Measuring tape or a ruler

- Zip ties or lashing straps

- Protective gloves (optional but recommended)

Pro Tip: Always opt for high-quality materials, especially when it comes to cargo net webbing. Compromising on material quality can lead to a weaker net that may not hold up under extreme stress or over time.

Understanding Cargo Net Webbing

The strength and durability of any cargo net primarily depend on the type of cargo net webbing used. This material is designed to handle the rigors of transportation, offering high resistance to environmental factors like UV exposure, rain, and temperature fluctuations.

Types of Cargo Net Webbing Materials

- Nylon Webbing

Nylon is well-known for its high tensile strength and elasticity. This material stretches under pressure, which can be advantageous when securing uneven loads. However, it has lower UV resistance than polyester and may degrade faster in outdoor environments. - Polyester Webbing

Polyester is highly regarded for its strength and UV resistance. It doesn’t stretch as much as nylon, which makes it ideal for more rigid and stable load security. For outdoor cargo nets, polyester is often the preferred choice because of its long-lasting durability in various weather conditions. - Polypropylene Webbing

While not as strong as nylon or polyester, polypropylene webbing is lightweight, water-resistant, and cost-effective. It’s suitable for light-duty applications or indoor use, but not recommended for heavy or outdoor loads.

Read it also: – Different Types of Cargo Net Webbing and Their Best Applications

Choosing the Right Width and Strength

The width and breaking strength of your cargo net webbing are crucial to the net’s performance. Webbing widths typically range from 1 inch to 2 inches, with wider webbing offering more strength and surface area for load distribution. When choosing your webbing, it’s essential to consider the type and weight of the cargo you’ll be securing.

- For light-duty applications, a 1-inch wide webbing may suffice.

- For heavy-duty applications, opt for 2-inch wide webbing with a high breaking strength.

Breaking Strength: Always check the breaking strength rating of the cargo net webbing before making a purchase. This is the maximum weight the webbing can handle before breaking. Polyester webbing, for example, often has a breaking strength of around 3,000 pounds per 2-inch width, making it ideal for securing large loads.

Step-by-Step Guide to Making a Cargo Net

Now that you have the materials ready, follow these steps to build your custom cargo net. Pay attention to detail and take the time to double-check your measurements to ensure the net will fit your needs perfectly.

Step 1: Measure and Cut the Cargo Net Webbing

First, measure the area where the cargo net will be used. For example, if you’re securing a load in the bed of a truck, measure the width and length of the truck bed. These measurements will determine how many strips of cargo net webbing you need and how long each strip should be.

- Pro Tip: When cutting cargo net webbing, ensure that each strip is slightly longer than the space you’re covering. This extra length will allow you to tie or sew the webbing securely at the edges.

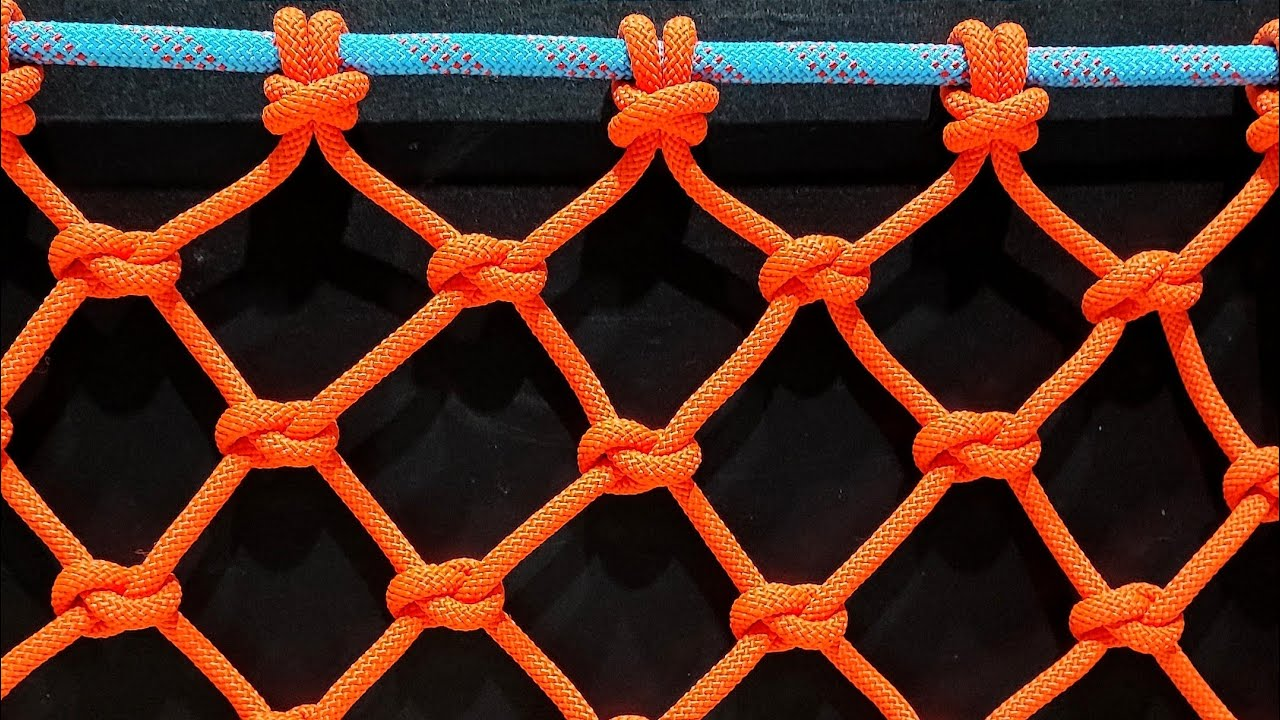

Step 2: Lay Out the Webbing in a Grid Pattern

Once you’ve cut the strips, lay them out on a flat surface in a grid pattern. Ensure the spacing between the strips is even; the typical spacing is 6 to 12 inches between each strip, but this can vary based on your needs.

- For a 6′ x 8′ cargo net, you’ll need approximately 8 horizontal and 8 vertical strips.

- If you’re securing smaller objects, use smaller spacing for a tighter net.

Step 3: Secure the Webbing at Intersections

At each point where the horizontal and vertical strips intersect, secure them using industrial-grade thread. For a more secure connection, you can also use zip ties or metal clamps. This is the most crucial part of the process, as the strength of these intersections determines the net’s overall durability.

- Sewing Method: Using a heavy-duty sewing machine, stitch multiple passes at each intersection to reinforce the grid structure. Make sure to use UV-resistant thread if the cargo net will be exposed to sunlight.

- Zip Ties or Clamps: If sewing isn’t feasible, you can use zip ties to secure the intersections. Zip ties are easier to use but may not be as durable as sewn intersections, so use this method for lighter loads.

Step 4: Attach Hooks or Carabiners

The next step is to attach hooks or carabiners to the edges of the cargo net, allowing you to easily secure the net to the vehicle or trailer. Focus on placing these at the corners and midpoints along the edges for the best load distribution.

- For heavier applications, metal carabiners or snap hooks are recommended.

- If using hooks, ensure they are corrosion-resistant, especially if the cargo net will be exposed to the elements.

Step 5: Test the Cargo Net

Once the cargo net is complete, it’s essential to test it before regular use. Secure it over a load and apply gentle pressure to ensure all connections are stable. Check that there’s no excessive stretch or weak points where the webbing could give out.

Testing Tips:

- Check the corners and intersections for any signs of fraying or weak stitching.

- Tug at the webbing to simulate the pressure it will experience during use.

- Ensure all hooks or carabiners are securely fastened and distribute the load evenly.

Common Mistakes to Avoid

When making your cargo net, there are a few common mistakes to avoid to ensure the net is strong, durable, and functional.

- Inconsistent Spacing Between Strips: Uneven spacing can lead to uneven load distribution, which could cause the cargo net to fail in certain areas. Always measure and mark the spacing between strips accurately.

- Weak Intersections: The points where the horizontal and vertical strips intersect are the most critical parts of the cargo net. If these points aren’t reinforced properly, the net will likely break under heavy pressure.

- Choosing the Wrong Webbing Material: Different types of cargo net webbing are suited for different applications. Make sure the material you choose can withstand the load and environmental conditions it will face.

Why Cargo Net Webbing Is Essential

Using cargo net webbing as the core material in your cargo net offers numerous advantages over other options like rope or bungee cords. Let’s explore why cargo net webbing is the superior choice:

- Even Load Distribution: Cargo net webbing distributes the load across the entire net, reducing pressure points that could cause items to shift or become damaged.

- High Durability: Unlike ropes, which can fray or lose strength over time, cargo net webbing is designed to withstand high pressure and harsh environmental conditions without losing its integrity.

- Weather Resistance: Polyester and nylon cargo net webbing are resistant to UV rays, moisture, and extreme temperatures, making them ideal for long-term outdoor use.

- Safety and Security: The use of webbing ensures that your cargo net remains strong even under significant strain, preventing accidents or load displacement during transportation.

Comparison of Common Cargo Net Materials

| Material | Tensile Strength | UV Resistance | Weather Resistance | Cost |

|---|---|---|---|---|

| Nylon | High | Low | Moderate | Moderate |

| Polyester | High | High | High | Moderate |

| Polypropylene | Moderate | Moderate | High | Low |

FAQs About Cargo Nets

Q1: Can I use a regular sewing machine to stitch cargo net webbing?

A: It’s highly recommended to use a heavy-duty sewing machine. Regular sewing machines may not be able to handle the thickness and durability requirements of industrial webbing, resulting in weak intersections.

Q2: How can I maintain my cargo net to ensure it lasts longer?

A: Regularly inspect the net for any frayed or damaged webbing. If the net is exposed to the elements, ensure that the webbing and stitching are UV-resistant. Cleaning the net with mild soap and water can help maintain its integrity, especially if it’s used in dusty or muddy conditions.

Q3: Can I add elastic bands to the cargo net?

A: Yes, adding elastic bands to the edges can provide some flexibility, allowing the net to stretch and secure unevenly shaped loads better.

Q4: What is the ideal spacing for cargo net webbing?

A: The standard spacing between webbing strips is around 6 to 12 inches, depending on the size of the items you’re securing. Smaller items require tighter spacing to prevent slipping through the net.

Q5: How do I know if my cargo net webbing is UV-resistant?

A: Check the specifications from the manufacturer. Polyester webbing is typically UV-resistant, while nylon is less so. Always opt for UV-resistant materials if the cargo net will be exposed to sunlight for extended periods.

Why Customization Matters

One of the key advantages of making your own cargo net is the ability to customize it according to your specific requirements, which can enhance your business visibility on Google My Business.You can tailor everything from the size and shape to the type of hooks or carabiners used. Some popular customizations include:

- Reflective Strips: For better visibility at night, especially in low-light conditions.

- Extra Reinforcement: Adding extra stitches or metal eyelets at stress points for added durability.

- Adjustable Straps: Incorporating adjustable straps can provide flexibility for securing different sizes and shapes of loads.

Different Applications for Cargo Nets

Cargo nets are versatile tools that can be used in a variety of settings, including:

- Vehicle Cargo Nets: For trucks, SUVs, and trailers.

- Warehouse and Industrial Use: To secure heavy equipment or products during storage and transport.

- Recreational Use: Ideal for securing outdoor gear, sports equipment, or camping supplies.

Contact Us

At Nets Depot Inc, we specialize in providing high-quality cargo net webbing and custom solutions to meet your transportation needs. If you need help selecting the right materials or have questions about the cargo net construction process, our team is here to help. Don’t hesitate to reach out to us for professional advice and recommendations.

Phone Contact: (305) 215-5579

Email Contact: [email protected]

By following this detailed guide, you can craft a durable cargo net that perfectly fits your needs, whether for personal, commercial, or industrial use. A well-made cargo net using high-quality cargo net webbing is an investment that will pay off in terms of load security and peace of mind.